| Check Valve - C | |||||||||||||||||||||||||||||||||||||||||

|

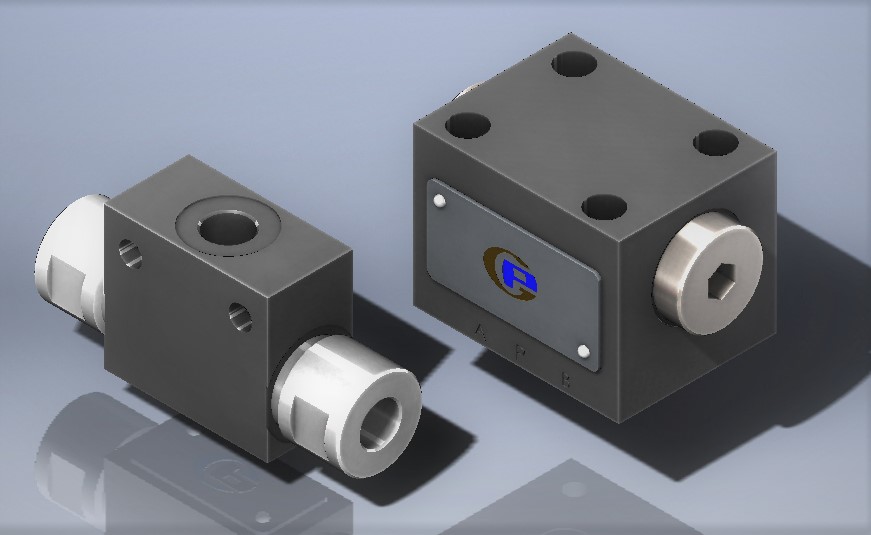

These seat type valves allow free flow from port A to port B and give leak-proof closure in opposite direction. Available as inline mounting or Sub-plate mounting as per factory & ISO standards.

|

|

||||||||||||||||||||||||||||||||||||||||

| Check Valve - C30T14 |

|

||||||||||||||||||||||||||||||||||||||||

| Check Valve - C (ISO) | |||||||||||||||||||||||||||||||||||||||||

|

Seat type valves. Allow free flow from port A to port Band

offer leakage free closure in opposite direction. Available in four sizes of standard

interfaces conforming to |

|

||||||||||||||||||||||||||||||||||||||||

| Check Valve - CI | |||||||||||||||||||||||||||||||||||||||||

|

Seat type valves, Model CI with internal drain. Threaded or Sub-plate mounting construction. Available with two pilot piston size options only for Model CI.

|

|

||||||||||||||||||||||||||||||||||||||||

| Check Valve - CI06 | |||||||||||||||||||||||||||||||||||||||||

|

Seat type valves, Model CI with internal drain. Threaded or Sub-plate mounting construction. Available with two pilot piston size.

|

|

||||||||||||||||||||||||||||||||||||||||

| Check Valve - CL | |||||||||||||||||||||||||||||||||||||||||

|

Seat type valves, CL with external drain. Threaded or Sub-plate mounting construction.

|

|

||||||||||||||||||||||||||||||||||||||||

| Check Valve - 2CI | |||||||||||||||||||||||||||||||||||||||||

|

These valves are available with the pilot operated check valve facility on either A or B or both A and B threaded ports. The hydraulic opening operation for free flow in reverse direction is achieved by means of internal pilot pressure available from the other working port. |

|

||||||||||||||||||||||||||||||||||||||||

| Pilot operated check valve (Modular) - CIM 06 | |||||||||||||||||||||||||||||||||||||||||

|

These modular valves are available with the pilot operated

check valve facility on either 'A' or 'B' ports. The hydraulic opening operation for free

flow in reverse direction is achieved by means of internal pilot pressure available from

the other working port. Interface conforming to

|

|

||||||||||||||||||||||||||||||||||||||||

| Pilot operated check valve (Modular) - CIM 10 | |||||||||||||||||||||||||||||||||||||||||

|

These modular valves are available with the pilot operated check valve facility on either A or B or both A and B ports. The hydraulic opening operation for free flow in reverse direction is achieved by means of internal pilot pressure available from the other working port. To ensure proper closure of both valve poppets, both user connections should be unloaded when the control valve is in the neutral position by connecting with the return line.

|

|

||||||||||||||||||||||||||||||||||||||||

| Shuttle Valves - SL | |||||||||||||||||||||||||||||||||||||||||

|

Seat type construction. Automatically connects it's P port to either A or B depending upon whichever of the two ports is at higher pressure level. Isolates port A and B from each other. Port P gets connected to tank, only if, port A and port B are connected to tank. Available both in Threaded and Sub-plate type.

|

|

||||||||||||||||||||||||||||||||||||||||

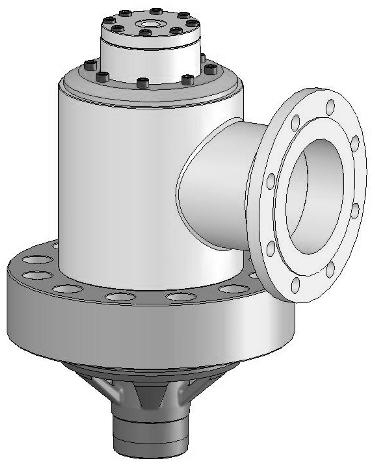

| Prefill valve (PV32 to PV80 ) | |||||||||||||||||||||||||||||||||||||||||

Intended for prefilling and exhausting of large hydraulic cylinders. Can be used as anticavitation check valves. Decompression feature is optional up to size 80.

|

|

||||||||||||||||||||||||||||||||||||||||

| Prefill valve (PV 100 to PV200 ) - 21 Series | |||||||||||||||||||||||||||||||||||||||||

|

The Prefill Exhaust Valve (PV) is a hydraulic-pilot operated check valve with seat type construction. It allows free flow from port A to port B. Flow from port B to port A can be enabled by applying pilot pressure to it's port X. The decompression feature enables the valve to open in two stages progressively, allowing smooth and rapid exhaust of the compressed oil. Opening and closing time of the valve can be influenced by providing Throttle-Check Valves in the X port line. Flanged port A of the valve housing can be rotated around vertical axis through 360° to facilitate access to flange fixing bolts and flange orientation Features

|

|||||||||||||||||||||||||||||||||||||||||

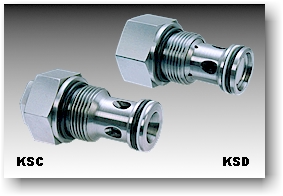

| Check Valve, SCREW-IN CARTRIDGE - KSC / KSD (Discontinued. Manufactured by : Hyloc Hydrotechnic Pvt. Ltd. Belgaum see www.hyloc.co.in) | |||||||||||||||||||||||||||||||||||||||||

| Two port screw-in cartridge

valves that are designed to fit in a cavity confirming to ISO 7789 : 1998

(E). These are seat type vales, available in four different sizes and with

five different cracking pressure in each size.

Check valves allow free flow in one direction while providing leak-free closure in reverse direction. Features

|

|

||||||||||||||||||||||||||||||||||||||||

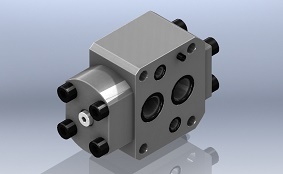

| By-pass Check Valve (Modular) - BCM -- (Discontinued) | |||||||||||||||||||||||||||||||||||||||||

|

Seat type modular valve. Intended for by - passing. Pressure control valve,Pressure reducing valve etc. to achieve reverse free flow condition.Allow free flow from port A to port B or from port B to port A ( see model code ) and offer leakage free closure in opposite direction. Available in four sizes of standard interfaces conforming to ISO 5781, DIN 24340 or IS 10187 Each model available with options of four cracking pressures : 0.5, 1.5, 3 and 5 bar.

|

|

||||||||||||||||||||||||||||||||||||||||